400G Optics – Form Factors QSFP-DD vs OSFP vs CFP8

With the rapid advancement of 5G and 400G Ethernet making waves in Data Centres – an important question needs to be answered. This question is – Which 400G Optics Form Factor is the best for linking the past to the future?

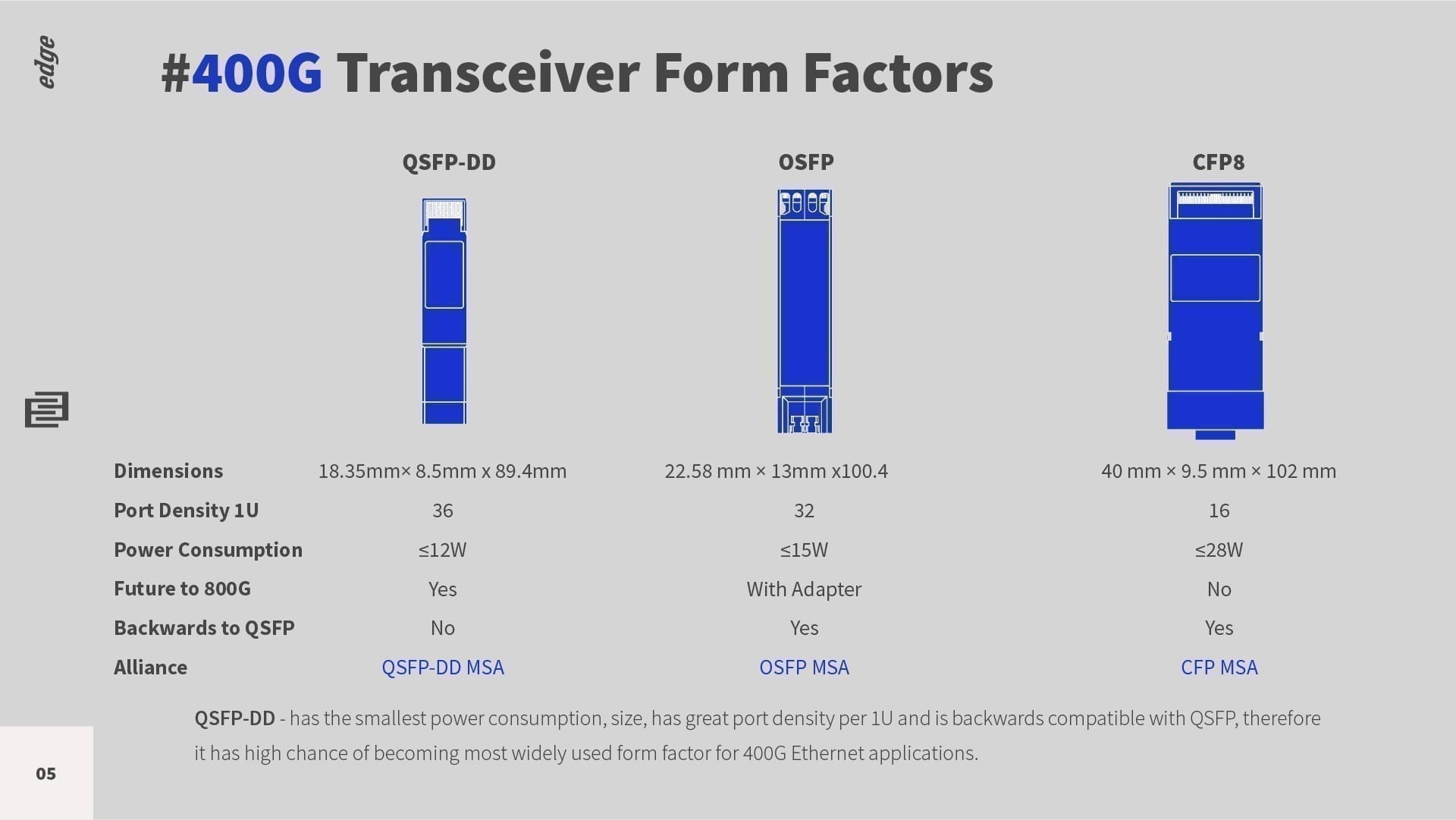

When talking about transceivers, form-factor and its capabilities play a vital role. Adding to this, widespread adaptation of 400G Optics is the next big step. That is why there is a debate on the best suited Form-Factor for 400G Optics. The main competing form factors are QSFP-DD, OSFP and CFP8. 400G Optics Form Factors shows comparison between said three form-factors.

Each form-factor has advantages and drawbacks. There will be applications and solutions that will utilize one of these QSFP-DD, OSFP or CFP8 form-factors to ensure maximum efficiency.

Form FactorQSFP-DDOSFPCFP8

| 400G Optics – QSFP-DD vs OSFP vs CFP8 | |||

|---|---|---|---|

| Dimensions | 18.35mm× 8.5mm x 89.4mm | 22.58 mm × 13mm x100.4 | 40 mm × 9.5 mm × 102 mm |

| Port Density 1U | 36 | 32 | 16 |

| Power Consumption | ≤12W | ≤15W | ≤28W |

| Future to 800G | No | Yes | Yes |

| Backwards to QSFP | Yes | With Adapter | No |

| Alliance | QSFP-DD MSA | OSFP MSA | CFP MSA |

However, QSFP-DD in current state looks like a favorite due to how much of industry is in love with QSFP form-factor and 100G QSFP28 modules. Additionally, QSFP-DD provides the highest Port Density compared to the competition. This gives QSFP-DD manufacturers much greater appeal than the new OSFP form-factor modules and bulkier CFP8 modules. Furthermore, QSFP-DD is developed to ensure backward compatibility with QSFP from-factor ports. Allowing for a more gradual upgrade from upgrade 100G QSFP28 systems to 400G capable solutions.

Nevertheless, Power Consumption – Maximum amount of Power that can be Dissipated by the module without damaging internal components – is of great importance. Main Power Consumption comes from Micro-Controller and PAM4 DSP that have to perform at mind boggling speed. Solutions are developed to improve efficiency of QSFP-DD to ensure internal component heating will be reduced below critical. An upside is the emergence of practical and applied EUV (Extreme Ultraviolet Lithography) that will reduce the power draw of logic components.